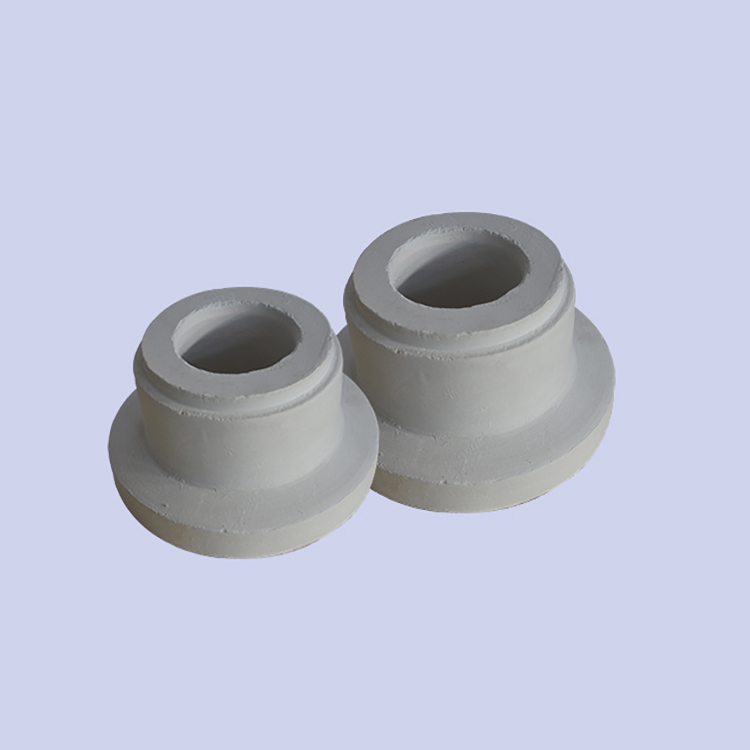

ceramic fiber tsau hmoov los kho launder system

Cov kua aluminium ntsug ntws yeeb nkab yog ua los ntawm cov khoom siv silicon molten tag nrho, muaj zog corrosion kuj, tsis muaj kuab paug rau cov hlau molten, thiab tuaj yeem siv ntau zaus kom tau raws li cov khoom muaj nqis ntxiv, kev ua haujlwm siab. ntawm aviation, tsheb thauj mus los thiab lwm yam aluminium alloy precision casting khoom technology xav tau.High-density, high-strength, high-silica (non-stick aluminium khoom) high-density thiab high-strength cam khwb cia txhuas conduit yog ib hom txhuas dej ntws yeeb nkab tshwj xeeb tsim rau kev lag luam txhuas hlau.Nws cov qauv tshwj xeeb ua rau nws muaj txiaj ntsig zoo thiab tuaj yeem siv rau Precision machined forming cov khoom, lub phaj muaj cov thermal conductivity, zoo thermal stability, anti-wetting thiab corrosion kuj, zoo heev machinability, thiab yuav siv tau los ua qee qhov ntawm aluminium alloy casting. , xws li: dropper, ntws yeeb nkab, kub sab saum toj nplhaib, nres pins, pob ntseg, floats, nruam casting tshuab nozzle khoom, tsis daim hlau, launder nco, machined standpipes thiab lwm yam aluminium industrial khoom.Lub synthesis ntawm tshwj xeeb kub resistant cov ntaub ntawv txiav txim siab hais tias lub txhuas kua standpipe muaj ntau yam ntxwv uas nyuaj rau hloov los ntawm lwm yam ntaub ntawv zoo xws li: kub tsis kam, thermal rwb thaiv tsev kev ua tau zoo, hluav taws xob rwb thaiv tsev kev ua tau zoo, tshuaj stability kev ua tau zoo, huab cua tsis kam, thiab lwm yam. tshwj xeeb tshaj yog kev nyab xeeb thiab kev tiv thaiv ib puag ncig.kev ua tau zoo, yog qhov zoo tshaj plaws hloov pauv rau lwm yam khoom siv phom sij.Cov khoom zoo: 1. Nws muaj qhov zoo ntawm lub zog siab, yaig tsis kam, cuam tshuam tsis kam, thermal shock resistance, thiab smoother nto;2. Nws tuaj yeem siv nrog boron nitride (BN) coatings, thiab lub neej kev pab cuam yog 50-100 lub sij hawm casting;3. Kev siv tau yooj yim thiab kev ua haujlwm, txhim khu kev siv cov khoom siv hluav taws xob hloov pauv hlau, thiab ua tiav kev txuag hluav taws xob thiab kev txo qis;Qhov zoo ntawm cov kua aluminium ntsug ntws yeeb nkab yog qhov yooj yim rau disassemble thiab sib sau ua ke, thiab tsis tas yuav tsum nres cov khoom siv thaum lub sijhawm teeb tsa.Cov khoom siv hluav taws kub-resistant thiab nplaim hluav taws tuaj yeem ua lub luag haujlwm ntawm kev sib khi thiab insulating tsuas yog los ntawm kev sib txuas cov yeeb nkab ntws los ntawm nruab nrab, uas tsis cuam tshuam rau kev tsim khoom thiab txuag nyiaj.lub sij hawm installation.Feem ntau siv rau hauv cov khoom siv smelting loj.