I. luv

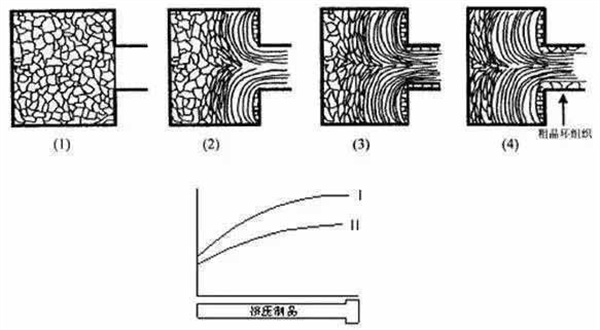

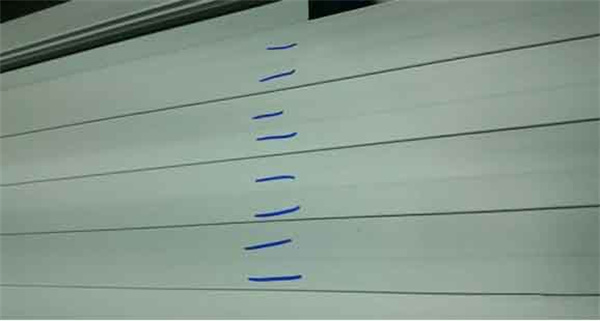

Nyob rau ntawm tus Tsov tus tw kawg ntawm qee cov khoom extruded, tom qab tsis tshua muaj kev soj ntsuam xyuas, muaj qhov tshwm sim zoo li horn nyob rau hauv nruab nrab ntawm qhov hla ntu, uas yog hu ua shrinking tail.

Feem ntau, tus Tsov tus tw ntawm cov khoom extrusion rau pem hauv ntej yog ntev dua li ntawm qhov rov qab extrusion, thiab cov mos mos alloy yog ntev dua li cov tawv tawv.Lub shrinkage ntawm cov khoom extruded rau pem hauv ntej yog feem ntau nyob rau hauv daim ntawv ntawm ib tug annular disjoint txheej, thiab lub shrinkage ntawm lub rov qab extruded khoom yog feem ntau nyob rau hauv cov duab ntawm ib tug central funnel.

Cov hlau yog extruded rau tom qab kawg, thiab cov ingot ntawm daim tawv nqaij thiab txawv teb chaws inclusions nyob rau hauv lub tuag ces kaum ntawm lub extrusion cylinder los yog gasket ntws mus rau hauv cov khoom los tsim ib tug thib ob shrinkage;thaum cov khoom seem yog luv dhau thiab qhov nruab nrab ntawm cov khoom noj tsis txaus, daim ntawv yog hom ntawv luv.Los ntawm qhov kawg ntawm tus Tsov tus tw mus rau pem hauv ntej, tus Tsov tus tw maj mam sib dua thiab ploj tag nrho.

Lub ntsiab ua rau shrinkage

1. Cov khoom seem yog luv dhau los yog qhov ntev ntawm qhov txiav qhov kawg ntawm cov khoom tsis ua raws li cov cai;

2. Lub extrusion ncoo tsis huv thiab muaj roj stains;

3. Nyob rau theem tom ntej ntawm extrusion, lub extrusion ceev ceev heev los yog dheev nce;

4. Siv lub deformed nyem pad (ib tug tsa lub ncoo nyob rau hauv nruab nrab);

5. Qhov kub ntawm lub tog raj kheej extrusion siab dhau lawm;

6. Lub tog raj kheej extrusion thiab lub extrusion ncej tsis sib haum;

7. Qhov saum npoo ntawm lub ingot tsis huv, muaj cov roj stains, cais cov qog thiab folding thiab lwm yam tsis xws luag tsis raug tshem tawm;

8. Lub tes tsho sab hauv ntawm lub tog raj kheej extrusion yog tsis huv los yog deformed, thiab lub hauv ob sab phlu tsis tau ntxuav nrog ib tug huv ncoo nyob rau hauv lub sij hawm.

Txoj kev tiv thaiv

1. Tshem tawm cov seem thiab txiav cov tails raws li xav tau;

2. Khaws cov pwm kom huv si;

3. Txhim kho qhov zoo ntawm qhov ingot;

4. Tsim nyog tswj lub extrusion kub thiab ceev kom zoo extrusion;

5. Tsuas yog cov xwm txheej tshwj xeeb, nws yog txwv tsis pub siv roj rau ntawm qhov chaw ntawm lub cuab yeej thiab pwm;

6. Lub gasket tau txias kom zoo.

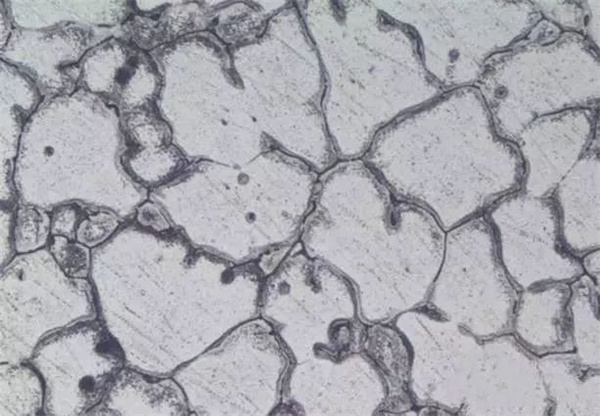

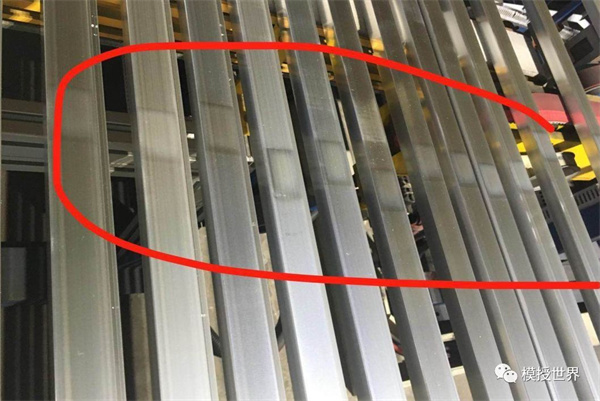

II.Coarse Crystal nplhaib

Qee cov khoom siv aluminium alloy extruded tsim ib coarse recrystallized grain qauv cheeb tsam raws li periphery ntawm cov khoom ntawm qhov tsawg magnification xeem piece tom qab kev daws teeb meem, uas yog hu ua ib coarse grain nplhaib.Vim muaj cov duab sib txawv thiab kev ua haujlwm ntawm cov khoom, lub nplhaib-puab, arc-puab thiab lwm yam ntaub ntawv ntawm coarse-grained rings tuaj yeem tsim.Qhov tob ntawm lub nplhaib coarse-grained maj mam txo los ntawm tus Tsov tus tw mus rau pem hauv ntej thiab ploj mus tag nrho.Lub hauv paus tsim mechanism yog thaj tsam sub-grain tsim nyob rau saum npoo ntawm cov khoom tom qab kub extrusion, thiab coarse recrystallized grain cheeb tsam yog tsim tom qab cua sov thiab kev kho mob.

Qhov laj thawj tseem ceeb ntawm coarse crystal nplhaib

1. Tsis sib xws extrusion deformation

2. Kev kho cua sov kub yog siab dhau thiab lub sijhawm tuav ntev dhau, kom cov nplej loj tuaj;

3. Cov tshuaj muaj pes tsawg leeg ntawm cov kub yog tsis tsim nyog;

4. Cov khoom siv hluav taws xob ua kom muaj zog ua kom muaj zog dav dav muaj cov nplhaib ntxhib tom qab kev kho cua sov, tshwj xeeb tshaj yog cov duab thiab cov tuav ntawm 6a02, 2a50 thiab lwm yam alloys yog qhov hnyav tshaj plaws, uas tsis tuaj yeem raug tshem tawm thiab tsuas yog tswj tau nyob rau hauv qee qhov ntau;

5. Lub extrusion deformation yog me me los yog deformation tsis txaus, los yog nyob rau hauv qhov tseem ceeb deformation ntau yam, thiab nws yog ib qho yooj yim los tsim ib coarse siv lead ua nplhaib.

Txoj kev tiv thaiv

1. Sab hauv phab ntsa ntawm lub tog raj kheej extrusion yog du thiab huv si, ua kom tiav lub tes tsho aluminium kom txo tau qhov kev sib txhuam thaum extrusion;

2. Lub deformation yuav tsum ua kom tag nrho thiab sib xws li qhov ua tau, thiab cov txheej txheem tsis xws li kub thiab ceev yuav tsum tswj kom muaj nuj nqis;

3. Zam kev kho qhov kub thiab txias siab dhau los yog lub sijhawm tuav ntev dhau lawm;

4. Extrusion nrog ntxeem tau tuag;

5. Extrusion los ntawm txoj kev rov qab extrusion thiab zoo li qub extrusion txoj kev;

6. Ua los ntawm kev daws teeb meem-kos duab-aging txoj kev;

7. Kho tag nrho cov kub muaj pes tsawg leeg thiab nce lub recrystallization inhibitory keeb;

8. Siv cov kub extrusion ntau dua;

9. Qee cov hlau ingots tsis yog homogenized, thiab lub nplhaib coarse yog qhov ntiav thaum lub sij hawm extrusion.

III, laiv

Qhov no yog daim tawv nqaij delamination tsis xws luag tsim thaum cov hlau ntws zoo ib yam, thiab qhov chaw ntawm lub ingot ntws mus rau hauv cov khoom raws li kev sib tshuam ntawm pwm thiab pem hauv ntej kawg elastic cheeb tsam.Nyob rau ntawm qhov transverse low-magnification test piece, nws zoo nkaus li tias muaj qhov tsis xws luag ntawm cov khaubncaws sab nraud povtseg ntawm ntug ntawm qhov hla ntu.

Lub ntsiab ua rau stratification

1. Muaj plua plav rau ntawm qhov chaw ntawm lub ingot los yog lub ingot muaj cov khoom sib cais loj es tsis txhob siv cov tawv nqaij ntawm lub tsheb, cov qog nqaij hlav hlau, thiab lwm yam, uas yog ib qho yooj yim rau txheej txheej;

2. Muaj burrs nyob rau saum npoo ntawm qhov khoob lossis cov av xws li cov roj stains, sawdust, thiab lwm yam, uas tsis tau ntxuav ua ntej extrusion;

3. Txoj hauj lwm ntawm lub qhov tuag yog qhov tsis tsim nyog, ze rau ntawm ntug ntawm lub tog raj kheej extrusion;

4. Cov cuab yeej extrusion yog hnav hnyav los yog muaj av nyob rau hauv bushing ntawm lub tog raj kheej extrusion, uas tsis tuaj yeem ntxuav thiab hloov lub sijhawm;

5. Qhov sib txawv ntawm qhov sib txawv ntawm cov ntaub qhwv extrusion yog loj heev;

6. Qhov kub ntawm lub tog raj kheej extrusion yog ntau dua li ntawm cov ingot.

Txoj kev tiv thaiv

1. Tsim nyog tsim pwm, tshawb xyuas raws sij hawm thiab hloov cov cuab yeej tsis tsim nyog;

2. Tsis tsim nyog ingots tsis raug ntsia rau hauv qhov cub;

3. Tom qab txiav cov khoom seem, nws yuav tsum tau ntxuav kom tsis txhob lo rau cov roj lubricating;

4. Khaws cov ntaub ntawv ntawm lub tog raj kheej extrusion tsis tu ncua, lossis ntxuav lub hauv ob sab hauv lub sijhawm nrog lub gasket.

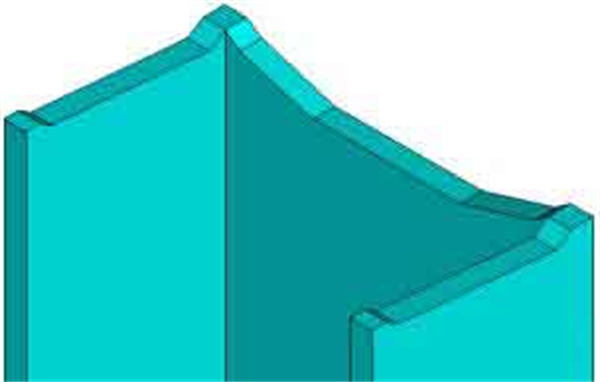

IV.Kev vuam tsis zoo

Qhov tshwm sim ntawm weld delamination lossis tsis tiav vuam ntawm cov khoom hollow extruded los ntawm kev sib cais tuag ntawm qhov vuam yog hu ua cov vuam tsis zoo.

Qhov laj thawj tseem ceeb ntawm kev vuam tsis zoo

1. Lub extrusion coefficient yog me me, extrusion kub yog tsawg, thiab extrusion ceev ceev;

2. Extrusion wool lossis cov cuab yeej tsis huv;

3. Roj pwm;

4. Kev tsim pwm tsis tsim nyog, tsis txaus lossis tsis muaj qhov sib npaug hydrostatic siab, tsim tsis tsim nyog ntawm shunt qhov;

5. Muaj roj stain nyob rau saum npoo ntawm lub ingot.

Txoj kev tiv thaiv

1. Ua kom cov extrusion coefficient, extrusion kub thiab extrusion ceev;

2. Tsim nyog tsim thiab tsim cov pwm;

3. Lub tog raj kheej extrusion thiab extrusion gasket tsis oiled thiab huv si;

4. Siv cov ingots nrog qhov chaw huv.

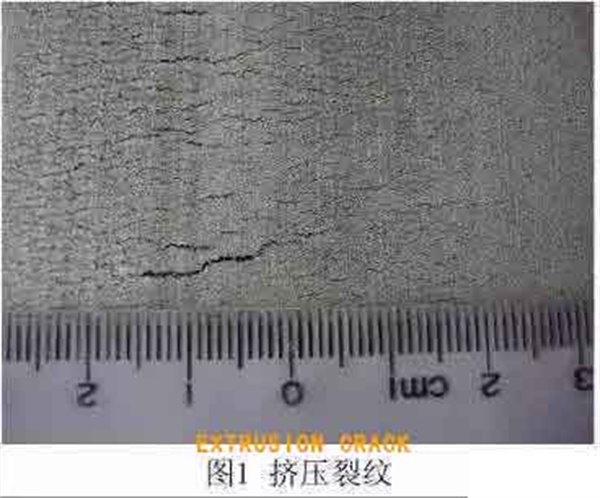

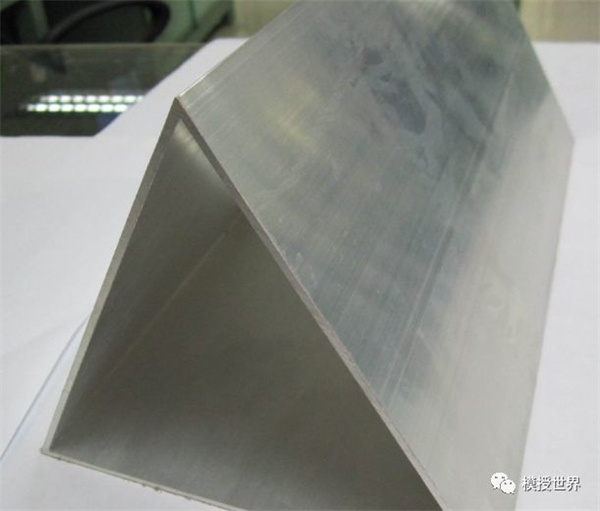

V. Extrusion tawg

Qhov no yog ib qho me me arc-puab tawg ntawm ntug ntawm qhov kev sib tw ntawm cov khoom extruded, thiab lub sijhawm tawg ntawm qee lub kaum sab xis raws nws cov kev taw qhia ntev, uas tau muab zais hauv qab ntawm daim tawv nqaij hauv lub teeb, thiab cov kab nrib pleb hauv txheej txheej. nyob rau hauv cov mob hnyav, uas yuav ua rau puas tsuaj rau qhov txuas ntxiv ntawm cov hlau.Extrusion kab nrib pleb yog tsim thaum cov hlau nto yog torn sib nrug los ntawm lub sij hawm ntev tensile kev nyuaj siab ntawm phab ntsa tuag thaum lub sij hawm extrusion txheej txheem.

Lub ntsiab ua rau extrusion tawg

1. Lub extrusion ceev ceev heev;

2. Extrusion kub siab dhau lawm;

3. Lub extrusion ceev fluctuates ntau dhau;

4. Qhov kub ntawm cov ntaub plaub extruded siab dhau lawm;

5. Thaum cov tuag ntxeem tau extruded, cov txheej txheem tuag yog ze rau qhov chaw, yog li cov khoom siv hlau hauv nruab nrab tsis txaus, yog li qhov sib txawv ntawm qhov nruab nrab thiab cov ntug dej ntws loj dhau;

6. Lub ingot homogenization annealing tsis zoo.

Txoj kev tiv thaiv

1. nruj me ntsis siv ntau yam cua sov thiab extrusion specifications;

2. Kev tshuaj xyuas ntau zaus ntawm cov cuab yeej thiab cov khoom siv kom ntseeg tau tias kev ua haujlwm ib txwm muaj;

3. Hloov kho pwm tsim thiab ua tib zoo ua nws, tshwj xeeb tshaj yog tsim cov pwm choj, vuam chav thiab ntug vojvoog, thiab lwm yam yuav tsum tsim nyog;

4. Txo cov ntsiab lus sodium hauv siab magnesium aluminium alloys;

5. Lub ingot yog homogenized thiab annealed los txhim kho nws cov plasticity thiab uniformity.

VI.npuas

Lub hauv paus ntawm daim tawv nqaij hlau yog tsis tu ncua los yog discontinuously sib cais los ntawm lub hauv paus hlau, thiab nws yog manifested raws li ib ncig ib ncig los yog strip-zoo li tus kab noj hniav tsa ceg, hu ua npuas.

Lub ntsiab ua rau npuas

1. Thaum extruding, lub tog raj kheej extrusion thiab extrusion ncoo muaj av xws li ya raws thiab roj;

2. Vim yog hnav ntawm lub tog raj kheej extrusion, huab cua nruab nrab ntawm qhov hnav thiab lub ingot nkag mus rau hauv cov hlau nto thaum lub sij hawm extrusion;

3. Muaj noo noo nyob rau hauv lub lubricant;

4. Lub ingot qauv nws tus kheej muaj xoob thiab porosity tsis xws luag;

5. Kev kho cua sov kub yog siab dhau, lub sijhawm tuav ntev dhau lawm, thiab huab cua noo nyob rau hauv lub cub tawg yog siab;

6. Cov ntsiab lus hydrogen hauv cov khoom yog siab dhau;

7. Extrusion lub tog raj kheej kub thiab ingot kub yog siab dhau.

Txoj kev tiv thaiv

1. Qhov chaw ntawm cov cuab yeej thiab cov ingots yuav tsum tau ua kom huv si, du thiab qhuav;

2. Tsim nyog tsim qhov sib txuam ntawm lub tog raj kheej extrusion thiab lub extrusion gasket, xyuas qhov loj ntawm cov cuab yeej nquag, kho lub extrusion cylinder nyob rau hauv lub sij hawm thaum muaj lub plab loj, thiab lub extrusion gasket yuav tsum tsis txhob tawm ntawm lub siab ntev;

3. Xyuas kom meej tias cov roj nplua nyeem huv thiab qhuav;

4. Ua raws li cov txheej txheem extrusion txheej txheem ua haujlwm, tso pa tawm hauv lub sijhawm, txiav kom raug, tsis txhob siv roj, tshem tawm cov khoom seem tag nrho, khaws cov blanks thiab pwm kom huv si thiab tsis muaj kuab paug.

VII.Peeling

Qhov no yog qhov tshwm sim ntawm kev sib cais hauv zos ntawm cov tawv nqaij hlau thiab lub hauv paus hlau ntawm aluminium alloy extrusion khoom.

Lub ntsiab ua rau ntawm peeling

1. Thaum cov hlau raug hloov thiab extruded, sab hauv phab ntsa ntawm lub tog raj kheej extrusion yog adhered rau lub hav txwv yeem tsim los ntawm cov hlau qub, uas tsis tau ntxuav kom zoo;

2. Lub tog raj kheej extrusion thiab cov ntaub ntawv extrusion tsis zoo sib xws, thiab sab hauv phab ntsa ntawm lub tog raj kheej extrusion yog lined nrog cov hlau seem hauv zos;

3. Nws yog extruded los ntawm lubricating extrusion lub tog raj kheej;

4. Muaj hlau ntawm lub qhov tuag los yog txoj siv sia ua haujlwm ntawm qhov tuag ntev dhau lawm.

Txoj kev tiv thaiv

1. Ua tib zoo ntxuav lub tog raj kheej extrusion thaum extruding alloy;

2. Tsim nyog tsim qhov sib luag ntawm lub tog raj kheej extrusion thiab lub extrusion gasket, xyuas cov cuab yeej loj ntau zaus, thiab cov extrusion gasket tsis tuaj yeem ua rau tsis kam;

3. Ntxuav cov hlau seem ntawm cov pwm hauv lub sijhawm.

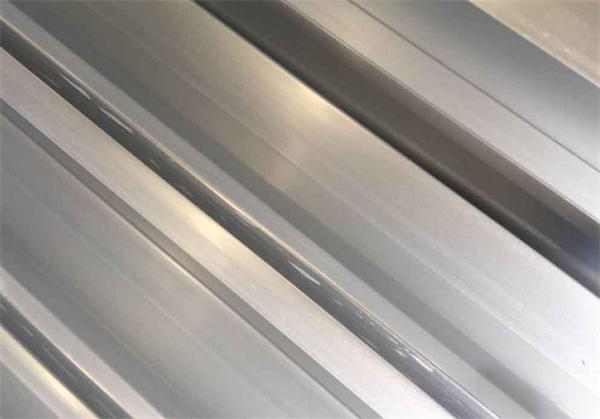

VIII.Kos

Ib leeg-striped mechanical scars tshwm sim los ntawm kev sib cuag ntawm cov khoom ntse thiab qhov chaw ntawm cov khoom thaum sib txheeb zawv zawg yog hu ua khawb.

Lub ntsiab ua rau khawb

1. Kev sib dhos tsis raug ntawm cov cuab yeej, cov lus qhia tsis zoo thiab cov rooj ua haujlwm, cov kaum ntse ntse lossis cov khoom txawv teb chaws, thiab lwm yam;

2. Muaj cov chips hlau ntawm cov pwm ua haujlwm siv los yog cov pwm ua haujlwm siv tau puas lawm;

3. Muaj cov xuab zeb lossis cov hlau tawg hauv cov roj lubricating;

4. Kev ua haujlwm tsis raug thaum lub sijhawm thauj mus los thiab cov khoom sib kis tsis zoo.

Txoj kev tiv thaiv

1. Tshawb xyuas thiab txhuam cov pwm ua haujlwm hauv lub sijhawm;

2. Tshawb xyuas cov channel tawm ntawm cov khoom, nws yuav tsum du, thiab cov kev taw qhia tuaj yeem lubricated kom zoo;

3. Tiv thaiv kev txhuam thiab khawb thaum tuav.

IX.Pob

Cov caws pliav tsim rau saum npoo ntawm cov khoom lossis cov khoom sib tsoo nrog lwm yam khoom yog hu ua pob raug mob.

Lub ntsiab ua rau pob

1. Cov qauv ntawm workbench thiab cov khoom khib nyiab tsis tsim nyog;

2. Kev tiv thaiv hlau tsis raug ntawm cov khoom siv pob tawb, cov khoom khib nyiab, thiab lwm yam .;

3. Tsis txhob ua tib zoo saib xyuas thaum ua haujlwm.

Txoj kev tiv thaiv

1. Ua haujlwm zoo, tuav nrog kev saib xyuas;

2. Sib tsoo cov ces kaum ntse, thiab npog lub pob tawb thiab khib nrog dunnage thiab cov ntaub ntawv mos.

X. Kos

Cov caws pliav muab faib rau hauv cov pob khoom ntawm qhov chaw ntawm cov khoom tshwm sim los ntawm cov txheeb ze zawv zawg lossis dislocation tom qab qhov chaw ntawm cov khoom extruded los rau hauv kev sib cuag nrog cov npoo los yog qhov chaw ntawm lwm yam khoom yog hu ua khawb.

Lub ntsiab ua rau khawb

1. Cov pwm yog hnav hnyav heev;

2. Vim lub siab kub ntawm lub ingot, qhov tuag qhov sticks rau txhuas los yog tuag qhov chaw ua hauj lwm txoj siv yog puas;

3. Cov av xws li graphite thiab roj poob rau hauv lub tog raj kheej extrusion;

4. Cov khoom txav mus rau ib leeg, kom qhov chaw yog khawb thiab cov extrusion ntws tsis sib xws, uas ua rau cov khoom tsis ntws mus rau hauv txoj kab ncaj nraim, ua rau khawb ntawm cov khoom siv thiab cov kev taw qhia thiab lub rooj ua haujlwm.

Txoj kev tiv thaiv

1. Tshawb xyuas thiab hloov cov pwm tsis tsim nyog raws sijhawm;

2. Tswj cov cua kub ntawm cov ntaub plaub;

3. Xyuas kom meej tias qhov chaw ntawm lub tog raj kheej extrusion thiab ntaub plaub huv huv thiab qhuav;

4. Tswj lub extrusion ceev kom ntseeg tau tias ceev ceev.

XI.Pwm cim

Qhov no yog ib txoj kab ntawm longitudinal unevenness nyob rau saum npoo ntawm cov khoom extruded, thiab tag nrho cov khoom extruded muaj cov cim tuag rau qhov sib txawv.

Qhov laj thawj tseem ceeb ntawm cov cim pwm

Qhov laj thawj tseem ceeb: cov pwm ua haujlwm siv tsis tuaj yeem ua tiav qhov smoothness.

Txoj kev tiv thaiv

1. Xyuas kom meej tias qhov saum npoo ntawm cov pwm ua haujlwm yog huv, du thiab tsis muaj cov npoo ntse;

2. Kev kho nitriding tsim nyog kom ntseeg tau tias muaj qhov tawv tawv siab;

3. Kho cov pwm kom raug;

4. Txoj siv sia ua haujlwm yuav tsum tsim kom tsim nyog, thiab txoj siv sia ua haujlwm yuav tsum tsis txhob ntev dhau.

XII.Twist, khoov, yoj

Qhov tshwm sim nyob rau hauv uas tus ntoo khaub lig seem ntawm cov khoom extruded yog angularly deflected nyob rau hauv lub longitudinal kev taw qhia yog hu ua twisting.Lub phenomenon uas cov khoom yog nkhaus nyob rau hauv lub longitudinal kev taw qhia los yog cov riam zoo tsis ncaj yog hu ua dabtsi yog khoov.Qhov tsis tu ncua undulating phenomenon uas tshwm sim nyob rau hauv longitudinal kev taw qhia ntawm cov khoom yog hu ua yoj.

Qhov laj thawj tseem ceeb ntawm kev sib tw, khoov, thiab nthwv dej

1. Kev tsim thiab kev teeb tsa ntawm qhov tuag qhov tsis zoo, lossis qhov loj me ntawm txoj siv ua haujlwm tsis tsim nyog;

2. Tsis zoo machining raug ntawm qhov tuag;

3. Cov lus qhia kom raug tsis raug ntsia;

4. Kev kho pwm tsis raug;

5. Extrusion kub thiab ceev;

6. Cov khoom tsis yog ua ntej ncaj nraim ua ntej kev kho mob;

7. Cov cua txias tsis sib xws thaum kho cua sov hauv online.

Txoj kev tiv thaiv

1. Qib siab ntawm pwm tsim thiab tsim khoom;

2. Nruab ib daim ntawv qhia tsim nyog, traction thiab extrusion;

3. Siv lub hauv paus lubrication, kho pwm thiab kev hloov pauv lossis hloov qhov tsim ntawm lub qhov shunt los kho cov hlau ntws;

4. Tsim nyog kho cov extrusion kub thiab ceev kom lub deformation ntau uniform;

5. Tsim nyog txo qhov kev kho qhov kub thiab txias los yog nce cov dej kub rau kev kho mob;

6. Ua kom zoo ib yam txias thaum lub sij hawm quenching online.

XIII.Khoov tawv

Kev khoov tam sim ntawd ntawm cov khoom extruded qhov chaw nyob rau hauv qhov ntev kev taw qhia yog hu ua ib qho nyuaj khoov.

Lub ntsiab ua rau tawv dabtsi yog khoov

1. Tsis sib xws extrusion ceev, hloov tam sim ntawd los ntawm kev kub ceev mus rau kev kub ceev, los yog cia li hloov los ntawm kev kub ceev mus rau tsawg ceev, thiab cia li nres;

2. Rigidly txav cov khoom thaum lub sij hawm extrusion txheej txheem;

3. Qhov chaw ua hauj lwm ntawm lub extruder yog tsis sib xws.

Txoj kev tiv thaiv

1. Tsis txhob nres ntawm random los yog hloov lub extrusion ceev dheev;

2. Tsis txhob txav qhov profile tam sim ntawd ntawm tes;

3. Xyuas kom meej tias lub rooj tso tawm yog tiaj tus thiab lub rooj tawm cov menyuam tawm yog du, tsis muaj teeb meem txawv teb chaws, thiab cov khoom sib xyaw ua ke tsis muaj kev cuam tshuam.

XIV.Hemp noodles

Qhov no yog qhov tsis xws luag ntawm cov khoom extruded, uas txhais tau hais tias qhov saum npoo ntawm cov khoom yog nruam flakes, qhov chaw khawb, pits, hlau taum, thiab lwm yam nrog me me unevenness.

Qhov laj thawj tseem ceeb ntawm pockmark

1. Lub hardness ntawm pwm tsis txaus los yog lub hardness tsis sib xws;

2. Extrusion kub siab dhau lawm;

3. Lub extrusion ceev ceev heev;

4. Txoj siv sia ua haujlwm ntawm cov pwm yog ntev dhau, ntxhib lossis daig nrog hlau;

5. Cov ntaub plaub extruded ntev dhau lawm.

Txoj kev tiv thaiv

1. Txhim kho lub hardness thiab hardness uniformity ntawm cov pwm ua hauj lwm siv;

2. Thaum tshav kub kub lub tog raj kheej extrusion thiab lub ingot raws li cov kev cai, thiab siv qhov tsim nyog extrusion ceev;

3. Tsim nyog tsim cov pwm, txo qhov roughness ntawm txoj siv sia ua haujlwm, thiab ntxiv dag zog rau kev tshuaj xyuas saum npoo, kho thiab polishing;

4. Siv qhov ntev ingot tsim nyog.

XV.Hlau nias

Thaum lub sij hawm extrusion txheej txheem, hlau chips yog nias rau hauv qhov chaw ntawm cov khoom, uas yog hu ua hlau nias.

Lub ntsiab ua rau hlau intrusion:

1. Cov ntaub plaub xaus yog faulty;

2. Sab hauv ntawm cov ntaub plaub yog daig nrog hlau lossis cov roj lubricating muaj cov khib nyiab hlau thiab lwm yam av;

3. Lub tog raj kheej extrusion tsis raug ntxuav, thiab muaj lwm yam hlau khib nyiab;

4. Lub ingot yog sunk rau hauv lwm yam khoom txawv teb chaws hlau;

5. Muaj slag suav nrog hauv cov ntaub plaub.

Txoj kev tiv thaiv

1. Tshem tawm cov burrs ntawm cov ntaub plaub;

2. Xyuas kom meej tias qhov chaw ntawm cov ntaub plaub thiab cov roj lubricating yog huv si thiab qhuav;

3. Ntxuav cov hlau khib nyiab hauv pwm thiab extrusion cylinder;

4. Xaiv cov ntaub plaub zoo.

XVI.Tsis yog hlau nias

Cov teeb meem txawv teb chaws xws li pob zeb dub yog nias rau sab hauv thiab sab nrauv ntawm cov khoom extruded, uas yog hu ua non-metallic indentation.Tom qab cov khoom txawv teb chaws raug muab tshem tawm, sab hauv ntawm cov khoom yuav pom kev nyuaj siab ntawm ntau qhov sib txawv, uas yuav rhuav tshem qhov txuas ntxiv ntawm qhov chaw ntawm cov khoom.

Qhov laj thawj tseem ceeb ntawm cov khoom tsis yog xim hlau intrusion

1. Lub graphite particle loj yog ntxhib los yog agglomerated, muaj noo noo los yog roj, thiab lub stirring yog uneven;

2. Lub flash point ntawm lub tog raj kheej roj yog tsawg;

3. Qhov piv ntawm lub tog raj kheej roj thiab graphite yog tsis tsim nyog, thiab muaj graphite ntau dhau.

Txoj kev tiv thaiv

1. Siv cov graphite tsim nyog thiab ua kom qhuav;

2. Lim thiab siv cov roj lubricating uas tsim nyog;

3. Tswj qhov piv ntawm lubricating roj thiab graphite.

XVII.Qhov saum npoo corrosion

Cov khoom siv extruded uas tsis tau txais kev kho saum npoo av, qhov chaw ntawm cov khoom extruded, tom qab cov tshuaj lom neeg los yog electrochemical cov tshuaj tiv thaiv nrog rau sab nraud nruab nrab, ua rau qhov tsis xws luag los ntawm kev puas tsuaj hauv cheeb tsam ntawm qhov chaw, uas yog hu ua deg corrosion.Qhov saum npoo ntawm cov khoom corroded poob nws cov xim hlau, thiab nyob rau hauv cov xwm txheej hnyav, grey-dawb corrosion khoom yog tsim rau ntawm qhov chaw.

Lub ntsiab ua rau ntawm qhov chaw corrosion

1. Cov khoom raug xa mus rau corrosive media xws li dej, kua qaub, alkali, ntsev, thiab lwm yam thaum lub sij hawm tsim khoom, khaws cia thiab kev thauj mus los, los yog nres hauv qhov chaw ntub dej ntev ntev;

2. Qhov sib piv ntawm cov alloy tsis zoo;

Txoj kev tiv thaiv

1. Khaws cov khoom nto thiab kev tsim khoom thiab chaw cia khoom kom huv si thiab qhuav;

2. Tswj cov ntsiab lus ntawm cov khoom hauv cov hlau.

XVIII.Txiv kab ntxwv tev

Qhov saum npoo ntawm cov khoom extruded muaj tsis sib xws wrinkles zoo li txiv kab ntxwv tev, kuj hu ua nto wrinkles.Nws yog tshwm sim los ntawm coarse nplej thaum extrusion.Lub coarser cov nplej, qhov pom tseeb qhov wrinkles.

Lub ntsiab ua rau txiv kab ntxwv tev

1. Cov qauv ingot tsis sib npaug thiab kev kho homogenization tsis txaus;

2. Cov xwm txheej extrusion tsis tsim nyog, thiab cov nplej ntawm cov khoom tiav yog ntxhib;

3. Tus nqi ntawm stretching thiab straightening yog loj heev.

Txoj kev tiv thaiv

1. Tsim nyog tswj cov txheej txheem homogenization;

2. Lub deformation yuav tsum zoo ib yam li qhov ua tau (tswj lub extrusion kub, ceev, thiab lwm yam)

3. Tswj qhov nro kho kom tsis txhob loj dhau.

XIX.Tsis sib xws

Tom qab extrusion, qhov chaw uas lub thickness ntawm cov khoom hloov ntawm lub dav hlau zoo nkaus li concave los yog convex.Feem ntau, nws tsis tuaj yeem pom ntawm qhov muag liab qab.Tom qab kev kho saum npoo, cov duab ntxoov ntxoo zoo los yog cov pob txha pob txha tshwm.

Qhov laj thawj tseem ceeb ntawm kev tsis sib xws

1. Cov pwm ua haujlwm siv tsis raug tsim, thiab kho pwm tsis nyob hauv qhov chaw;

2. Qhov loj ntawm lub qhov shunt los yog lub pre-chamber tsis haum, thiab lub zog ntawm rub los yog nthuav cov profile nyob rau hauv tus ntoo khaub lig cheeb tsam ua rau ib tug me ntsis kev hloov nyob rau hauv lub dav hlau;

3. Cov txheej txheem cua txias tsis sib npaug, thiab qhov cua txias ceev ntawm qhov tuab-walled los yog qhov sib tshuam yog qeeb, uas ua rau qhov sib txawv ntawm qhov shrinkage thiab deformation ntawm lub dav hlau thaum lub caij txias;

4. Vim muaj qhov sib txawv loj ntawm thickness, qhov sib txawv ntawm qhov tuab-walled ib feem los yog lub koom haum hloov chaw thiab lwm qhov chaw ntawm lub koom haum nce.

Txoj kev tiv thaiv

1. Txhim kho qib pwm tsim, tsim thiab kho pwm;

2. Ua kom cov cua txias tsis sib xws.

XX.Vibration qauv

Qhov no yog ib tug periodic streak defect transverse mus rau saum npoo ntawm cov khoom extruded.Nws yog tus cwj pwm los ntawm kab rov tav ncua sij hawm kab txaij nyob rau saum npoo ntawm cov khoom, thiab cov kab txaij nkhaus zoo ib yam nrog cov duab ntawm txoj siv sia ua haujlwm ntawm pwm, thiab nyob rau hauv cov xwm txheej hnyav, muaj qhov pom tseeb ntawm kev xav.

Qhov tseem ceeb ntawm kev vibration

1. Lub extrusion ncej txav mus rau pem hauv ntej thiab co vim yog vim li cas cov khoom siv, uas ua rau cov hlau co thaum nws ntws tawm ntawm lub qhov;

2. Cov hlau co thaum nws ntws tawm ntawm qhov tuag vim yog pwm;

3. Cov pwm txhawb nqa lub ncoo tsis haum, pwm rigidity tsis zoo, thiab kev vibration tshwm sim thaum lub zog extrusion hloov pauv.

Txoj kev tiv thaiv

1. Siv cov pwm tsim nyog;

2. Cov ntaub ntawv txhawb nqa tsim nyog yuav tsum tau siv thaum lub pwm raug teeb tsa;

3. Kho cov khoom siv.

XXI, Sib

Qhov laj thawj tseem ceeb ntawm kev suav nrog

Txij li thaum lub inclusion billet muaj hlau los yog non-hlau inclusions, nws tsis tau pom nyob rau hauv cov txheej txheem dhau los, thiab tseem nyob rau saum npoo los yog hauv cov khoom tom qab extrusion.

Txoj kev tiv thaiv

Ntxiv dag zog rau kev soj ntsuam ntawm lub billet (nrog rau kev soj ntsuam ultrasonic) kom tsis txhob muaj cov hlau lossis cov hlau tsis muaj hlau los ntawm kev nkag mus rau cov txheej txheem extrusion.

XXII, Water marks

Lub teeb dawb los yog lub teeb dub tsis xwm yeem waterline cim rau ntawm qhov khoom yog hu ua cov cim dej.

Lub ntsiab ua rau cov cim dej

1. Lub ziab tsis zoo tom qab ntxuav, thiab muaj cov dej seem seem ntawm cov khoom;

2. Cov dej seem seem ntawm qhov chaw ntawm cov khoom tshwm sim los ntawm nag thiab lwm yam laj thawj tsis tau raug ntxuav raws sij hawm;

3. Cov roj ntawm cov hluav taws kub nyhiab muaj dej, thiab cov dej condenses rau ntawm qhov chaw ntawm cov khoom thaum lub sij hawm txias ntawm cov khoom tom qab kev laus;

4. Cov roj ntawm lub cub hluav taws xob laus tsis huv, thiab qhov chaw ntawm cov khoom yog corroded los ntawm cov sulfur dioxide tom qab combustion los yog polluted los ntawm hmoov av;

5. Qhov nruab nrab quenching yog qias neeg.

Txoj kev tiv thaiv

1. Khaws qhov chaw ntawm cov khoom kom qhuav thiab huv si;

2. Tswj cov dej noo thiab kev huv ntawm kev laus;

3. Txhim khu kev tswj ntawm quenching nruab nrab.

XXIII.Qhov txawv

Tus kav yog horizontally superimposed ntawm ib lub dav hlau ntawm cov khoom extruded, thiab muaj qee qhov sib txawv ntawm tus pas ntsuas thiab qhov chaw, uas yog hu ua qhov sib txawv.

Qhov laj thawj tseem ceeb ntawm qhov sib txawv

Cov hlau tsis sib xws thaum lub sij hawm extrusion lossis kev ua tiav tsis tiav thiab kev ua haujlwm ncaj.

Txoj kev tiv thaiv

Tsim thiab tsim pwm tsim nyog, ntxiv dag zog rau kev kho pwm, thiab tswj qhov kub thiab txias extrusion ceev raws li kev cai nruj.

XXIV, Uneven phab ntsa thickness

Extruded khoom ntawm tib lub loj muaj nyias los yog tuab phab ntsa nyob rau hauv tib seem los yog longitudinal kev taw qhia, thiab qhov tshwm sim yog hu ua tsis sib xws phab ntsa thickness.

Qhov laj thawj tseem ceeb ntawm cov phab ntsa tsis sib xws

1. Cov pwm tsim yog tsis tsim nyog, los yog cov cuab yeej thiab pwm sib dhos yog tsis tsim nyog;

2. Lub tog raj kheej extrusion thiab cov koob extrusion tsis nyob rau tib qhov chaw, tsim eccentricity;

3. Cov txheej txheem ntawm lub tog raj kheej extrusion yog hnav ntau dhau, thiab cov pwm tsis tuaj yeem ruaj khov, ua rau eccentricity;

4. Cov phab ntsa tsis sib luag ntawm qhov ingot dawb paug nws tus kheej tsis tuaj yeem raug tshem tawm tom qab thawj zaug thiab thib ob extrusion.Cov phab ntsa tsis sib luag ntawm cov ntaub plaub tom qab extrusion tsis raug tshem tawm tom qab dov thiab ncab;

5. Cov roj lubricating tsis sib npaug, uas ua rau cov hlau ntws tsis sib xws.

Txoj kev tiv thaiv

1. Ua kom zoo rau kev tsim thiab tsim cov cuab yeej thiab pwm, thiab sib dhos thiab kho kom zoo;

2. Kho qhov chaw ntawm extruder thiab extrusion tuag;

3. Xaiv cov blanks uas tsim nyog;

4. Tsim nyog tswj ntawm extrusion kub, extrusion ceev thiab lwm yam txheej txheem tsis.

XXV.Nthuav (thiab) lub qhov ncauj

Qhov tsis xws luag uas ob sab ntawm cov khoom extruded profile xws li zawj thiab I-shaped inclined sab nraud yog hu ua flaring, thiab qhov tsis xws luag uas yog inclined sab hauv yog hu ua parallel qhib.

Cov laj thawj tseem ceeb ntawm kev nthuav dav (kev sib koom ua ke)

1. Cov hlau ntws tus nqi ntawm ob "sab ceg" (los yog ib "sab ceg") ntawm lub trough los yog zoo sib xws trough profiles los yog I-shaped profiles tsis sib xws;

2. Tus nqi ntws ntawm txoj siv ua haujlwm ntawm ob sab ntawm qhov zawj hauv qab phaj tsis sib npaug;

3. Tsis tsim nyog stretch straightening tshuab;

4. Tom qab cov khoom tawm ntawm lub qhov pwm, cov kev kho mob hauv online yog tsis sib npaug.

Txoj kev tiv thaiv

1. nruj me ntsis tswj lub extrusion ceev thiab extrusion kub;

2. Xyuas kom muaj qhov sib xws ntawm cov cua txias;

3. Tsim thiab tsim cov pwm kom raug;

4. nruj me ntsis tswj lub extrusion kub thiab ceev, thiab nruab lub cuab tam thiab tuag kom raug.

XXVI.Straightening cov cim

Cov helical streaks tsim thaum lub yob sab sauv ntawm cov khoom extruded ncaj yog hu ua cov cim ncaj, thiab cov qhab nias tsis tuaj yeem zam rau txhua yam khoom ncaj nraim los ntawm lub yob sab saud.

Qhov laj thawj tseem ceeb ntawm kev ncaj nraim

1. Muaj cov npoo ntawm cov menyuam nto ntawm cov menyuam ncaj;

2. Kev khoov ntawm cov khoom loj heev;

3. Siab dhau heev lawm;

4. Lub kaum sab xis ntawm cov menyuam straightening yog loj heev

5. Cov khoom muaj ovality loj.

Txoj kev tiv thaiv

Siv cov kev ntsuas tsim nyog los kho raws li qhov ua rau.

XXVII.Nres cov cim, cov kev xav tau tam sim, cov cim tom

Nres extrusion thaum lub sij hawm extrusion los tsim kab txaij ntawm qhov chaw ntawm cov khoom thiab perpendicular mus rau extrusion kev taw qhia, hu ua nres cov cim;kab los yog kab txaij kab txaij nyob rau saum npoo ntawm cov khoom thiab perpendicular mus rau lub extrusion kev taw qhia thaum lub sij hawm extrusion, hu ua tom cov cim los yog tam sim no impressions (feem ntau hu ua "fake chaw nres tsheb cim")

Thaum lub sij hawm extrusion, cov ntawv txuas uas ruaj khov rau saum npoo ntawm txoj siv sia ua haujlwm yog tam sim ntawd tshem tawm thiab ua raws li cov khoom siv extruded los tsim cov qauv.Kab rov tav kab txaij ntawm txoj siv sia ua haujlwm uas tshwm sim thaum lub extrusion nres yog hu ua qhov chaw nres tsheb;cov kab txaij uas tshwm sim thaum lub sij hawm extrusion txheej txheem hu ua instant impressions los yog tom cov cim, thiab lawv yuav ua suab nrov thaum extrusion.

Qhov laj thawj tseem ceeb ntawm cov cim nres, cov cim tam sim, thiab cov cim tom

1. Cov cua kub tsis sib xws ntawm ingot los yog tam sim ntawd hloov nyob rau hauv extrusion ceev thiab siab;

2. Qhov tseem ceeb ntawm cov pwm yog tsim thiab tsim tsis zoo, los yog kev sib dhos tsis sib xws thiab muaj qhov khoob;

3. Muaj lub zog sab nraud perpendicular mus rau extrusion kev taw qhia;

4. Lub extruder tsis khiav zoo, thiab muaj qhov tshwm sim ntawm kev nkag.

Txoj kev tiv thaiv

1. Qhov kub thiab txias, qeeb ceev thiab zoo li extrusion, lub zog extrusion tseem ruaj khov;

2. Tiv thaiv kev quab yuam sab nraud nyob rau hauv txoj kab ntsug extrusion los ntawm kev ua ntawm cov khoom;

3. Tsim nyog tsim cov cuab yeej thiab cov pwm, xaiv cov khoom pwm kom raug, qhov sib txuam me me, lub zog thiab hardness.

XXVIII.Kos rau ntawm sab hauv

Cov khawb ntawm sab hauv ntawm cov khoom extruded thaum lub sij hawm extrusion txheej txheem hu ua puab nto khawb.

Qhov laj thawj tseem ceeb ntawm kev puas tsuaj sab hauv

1. Lub koob extrusion yog daig nrog hlau;

2. Qhov kub ntawm cov koob extrusion yog tsawg;

3. Qhov zoo ntawm qhov extrusion koob yog qhov tsis zoo thiab muaj pob;

4. Lub extrusion kub thiab ceev tsis zoo tswj;

5. Kev sib piv tsis raug ntawm extrusion lubricant;

Txoj kev tiv thaiv

1. Ua kom qhov kub thiab txias ntawm lub tog raj kheej extrusion thiab extrusion koob, thiab tswj lub extrusion kub thiab extrusion ceev;

2. Txhim kho cov roj lubricating kom pom, xyuas lossis hloov cov roj khib nyiab ntau zaus, thiab siv cov roj sib npaug thiab tsim nyog;

3. Khaws cov ntaub plaub kom huv si;

4. Hloov cov pwm tsis tsim nyog thiab cov koob extrusion nyob rau lub sijhawm, thiab ua kom lub ntsej muag ntawm extrusion pwm huv si thiab du.

XXX.Lwm yam

Nyob rau hauv ib lo lus, tom qab kev kho mob zoo, 30 yam tsis xws luag ntawm cov saum toj no-hais aluminium alloy extrusion khoom yuav raug tshem tawm zoo, zoo, siab yield, ntev lub neej, thiab zoo nkauj khoom nto, tsim ib lub hom phiaj, coj vitality thiab kev vam meej rau lub kev lag luam, thiab muaj cov txiaj ntsig kev lag luam thiab nyiaj txiag tseem ceeb.

XXX.Lwm yam

Nyob rau hauv ib lo lus, tom qab kev kho mob zoo, 30 yam tsis xws luag ntawm cov saum toj no-hais aluminium alloy extrusion khoom yuav raug tshem tawm zoo, zoo, siab yield, ntev lub neej, thiab zoo nkauj khoom nto, tsim ib lub hom phiaj, coj vitality thiab kev vam meej rau lub kev lag luam, thiab muaj cov txiaj ntsig kev lag luam thiab nyiaj txiag tseem ceeb.

Post lub sij hawm: Aug-14-2022