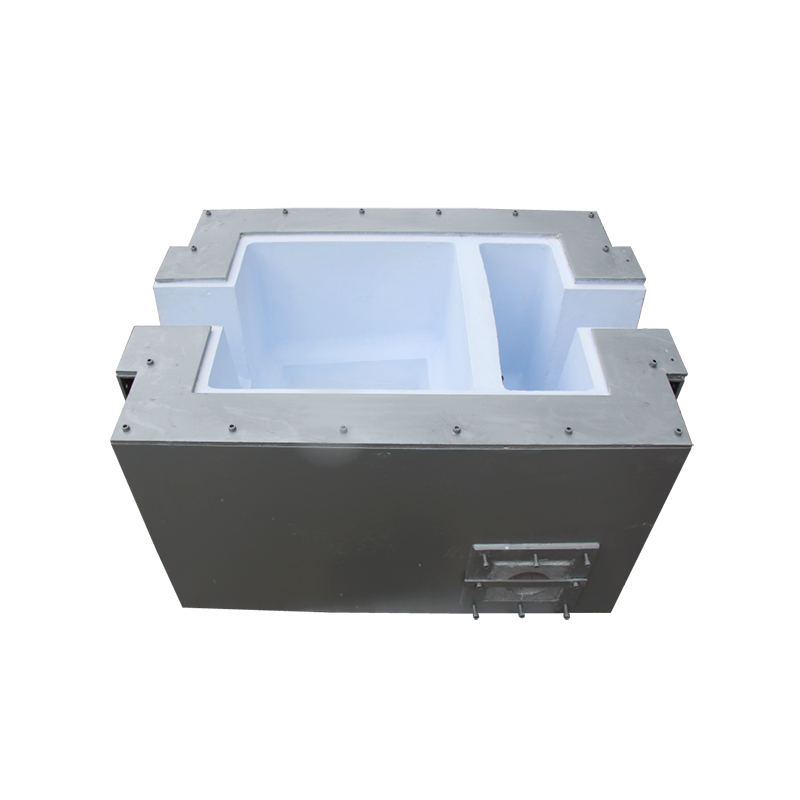

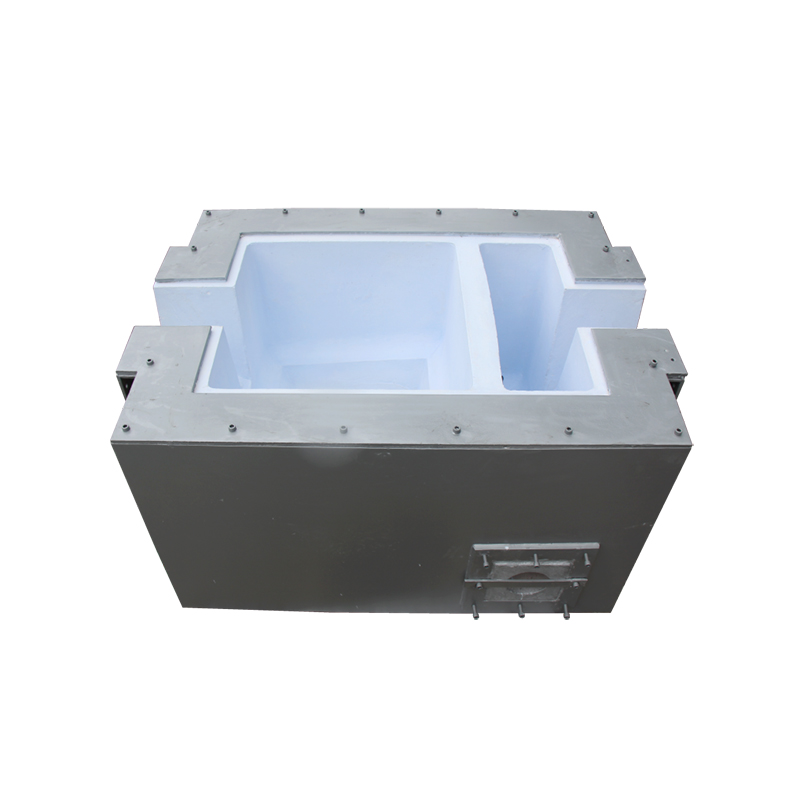

lim lub thawv nrog ceramic lim board filtering molten aluminium

Lub graphite phaj ntawm qhov tawm ntawm aluminium extrusion xovxwm plays lub luag haujlwm lubricating.Feem ntau, ntau coarse-grained graphite yog siv.High-purity graphite yog zoo thiab du, thiab qhov tshwm sim ntawm khawb cov khoom siv txhuas yog me me heev.Siv cov khoom siv high-purity no yuav ua rau kom muaj kev pab cuam lub neej thiab txuag cov nqi kuj.

Khoom npe: Aluminium profile graphite ntawv

Cov yam ntxwv ntawm cov khoom: kev ua haujlwm tshwj xeeb Kev tsim khoom ntawm ntau yam khoom siv graphite, uas tuaj yeem ua raws li cov neeg siv khoom xav tau!

1.Yog tias koj muaj cov duab kos, thov xa cov duab kos (CAD, PDF, kos duab kos duab).

2. Piav qhov loj, ntau, tuab, thiab lwm yam.

3.Kev txiav txim siab cov txheej txheem kev ua haujlwm (kev txiav yooj yim, xuas nrig ntaus, kev cai ua heterosexual qhov chaw, sib tsoo, milling thiab txiav txiav, thiab lwm yam).

4.Kev them nyiaj tuaj yeem ua tom qab hais lus.

Nco tseg:Yog tias qhov loj me yuav tsum tau ua kom raug tshwj xeeb, thov piav qhia, vim tias yuav muaj qee qhov kev zam rau cov txheej txheem ib txwm muaj xws li txiav, sib tsoo thiab xuas nrig ntaus.Yog tias muaj cov kev xav tau tshwj xeeb rau qhov tshwj xeeb-zoo li tus, nws yuav tsum tau piav qhia ua ntej.Kev ua tib zoo ua tib zoo Nta: 1 Zoo kub tsis kam 2 Lubrication thiab hnav tsis kam 3 Zoo thermal conductivity 4 Kev cai precision machining

Haum rau cov ntawv thov casting nrog reticulated ceramic ua npuas ncauj pom.

1. Nws tuaj yeem siv ncaj qha rau ntawm chav tsev kub yam tsis muaj kev txhawj xeeb txog thermal shock.

2. Tsis muaj thermal expansion thiab thermal conductivity tsawg.

3. Nws tuaj yeem ntab hauv txhuas, txo qhov muaj peev xwm ntawm refractory inclusions.

1. Ntxuav lub thawv lim.

2. Maj mam muab lub phaj lim tso rau hauv lub thawv lim, thiab nias lub sealing gasket nyob ib ncig ntawm lub phaj lim los ntawm txhais tes kom tsis txhob ntws ntawm molten aluminium.

3. Preheat lub thawv lim thiab lim phaj tusyees kom lawv nyob ze rau qhov kub ntawm cov molten aluminium.Preheat kom tshem tawm cov dej noo thiab yooj yim rau thawj zaug pom.Preheating tuaj yeem nqa tau siv hluav taws xob lossis roj cua sov.Raws li ib txwm muaj, nws yuav siv li 15--30 feeb.

4. Ua tib zoo saib qhov kev hloov ntawm aluminium hydraulic lub taub hau thaum casting.Lub taub hau ib txwm pib siab yog 100-150mm.Thaum lub molten aluminium pib dhau, lub taub hau siab yuav poob qis dua 75--100mm, thiab tom qab ntawd lub taub hau siab yuav maj mam nce.

5. Thaum lub sij hawm ib txwm pom cov txheej txheem, tsis txhob khob thiab vibrating lub lim phaj.Nyob rau tib lub sijhawm, cov ntxhua khaub ncaws yuav tsum tau ntim nrog cov dej txhuas kom tsis txhob muaj kev cuam tshuam ntau dhau ntawm cov dej txhuas.

6. Tom qab kev pom, tshem tawm cov phaj lim hauv lub sijhawm thiab ntxuav lub thawv lim.

Kev tsim cov qauv loj, muab kev txhawb nqa txhim khu kev qha kom paub tseeb qhov ua tau zoo ntawm cov npuas dej ceramic lim phaj.Ntxiv nrog rau cov lus qhia dav dav, nws tuaj yeem tsim thiab tsim raws li cov neeg siv khoom xav tau.