Dej Mist Quenching System Rau Aluminium Profile Extrusion Tshuab

1. Nws tuaj yeem ua tau raws li qhov xav tau ntawm lub zog txias ntawm cov hlau sib txawv thiab xyuas kom meej cov khoom siv ntawm cov khoom.

2. Ua tau zoo txo qhov deformation ntawm profiles thiab xyuas kom meej qhov tseeb ntawm cov khoom.

3. Txhim kho qhov kis tau zoo.

4. Cov nyhuv txuag hluav taws xob yog qhov pom tseeb, thiab cov nqi tsim khoom raug txo kom zoo.

5. Yooj yim rau kev khiav lag luam thiab txo qhov kev cia siab ntawm kev ua haujlwm.

1. Plaub-hauv-ib lub luag haujlwm ntawm huab cua txias, huab cua-mist sib xyaw, huab cua txias thiab siab-siab jetting.

Raws li qhov rhiab heev ntawm cov hlau sib txawv quenching rau lub zog txias, thiab cov phab ntsa sib txawv, cov ntawv txias sib txawv raug xaiv.- Cov huab cua-mist sib xyaw muaj kev siv zog ntau dua li cua txias, txo qis kev siv zog.

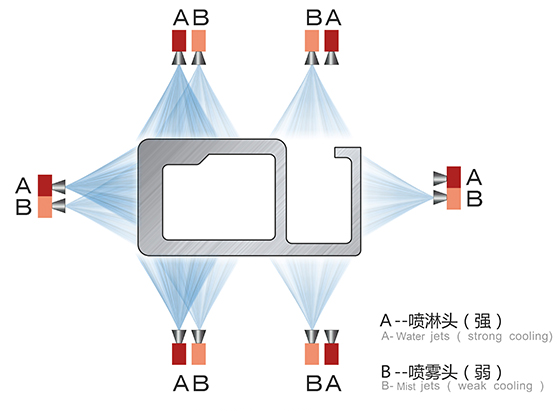

2.Circumferential multi-channel nozzle ntws txawv kev hloov kho muaj nuj nqi.

Lub zog txias tuaj yeem hloov kho raws li qhov sib txawv ntawm phab ntsa thickness ntawm qhov profile, uas tuaj yeem txo qhov deformation ntawm qhov profile.

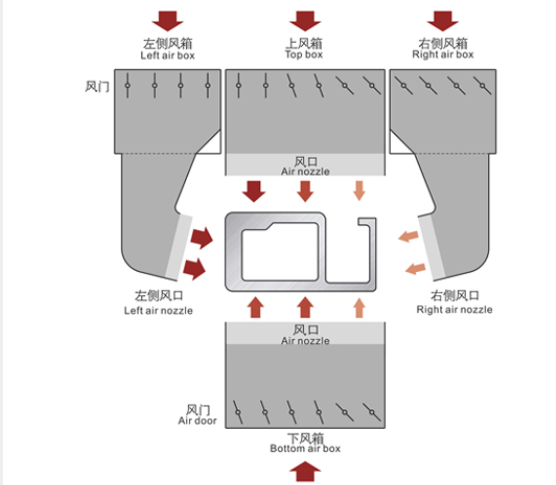

3. Circumferential multi-kem cua qhov hluav taws xob thiab hloov cua ntim

Lub kaw lus tau txais cov qauv tsim ntawm cov kab hluav taws xob ntau lub voj voog, thiab cov cua ntim thiab cua siab ntawm txhua kab tuaj yeem hloov kho.

Txhua txoj haujlwm ntawm extruded profile tuaj yeem ua kom txias tsis sib xws, txo qis deformation.

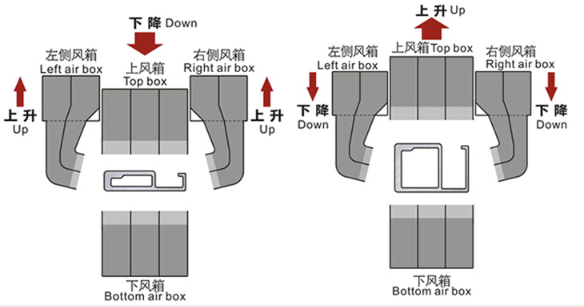

4. Lub tuyere hauv nruab nrab thiab tuyere ntawm ob sab tuaj yeem hloov kho nce thiab nqis (rau cov tshuab loj tonnage)

Lub qhov cua sab saum toj thiab ob sab cua vents tuaj yeem hloov kho nce thiab nqis kom haum rau qhov siab ntawm qhov profile.Cov qauv no yog ib qho tseem ceeb tshwj xeeb rau cov khoom siv quenching loj.Tib functionality rau sib xws mounted dej-txias sprinklers.

5. Tib neeg-tshuab interface tswj thiab parameter nco muaj nuj nqi

Txiv neej-tshuab interface tswj, txhua yam kev ua thiab kev hloov kho ntawm lub kaw lus tuaj yeem tswj tau los ntawm tus txiv neej-tshuab interface, uas yooj yim rau kev khiav lag luam.Parameter nco muaj nuj nqi, txhawm rau txhim kho kev ua tau zoo ntawm kev hloov kho, lub kaw lus tswj tau tsim lub cim xeeb ua haujlwm.Txhua qhov txheej txheem tsim nyog yuav raug sau tseg, thiab lub sijhawm tom ntej ntawm tib cov khoom tsim tawm, lub kaw lus yuav hu rau cov cim cim rau kev tsim khoom.Lub kaw lus muaj cov chaw taws teeb debugging, saib xyuas thiab tu ua haujlwm.