Kub Sab saum toj Billet Nruam Casting Tshuab Rau Aluminium Foundry

Xws li ruber, hydraulic cable, zoo khib, lifter, steel hlua, guiding roller system.

Puller yog ua los ntawm lub cev muaj zog, iav loj reducer, steel hlua, khib thiab lwm yam.

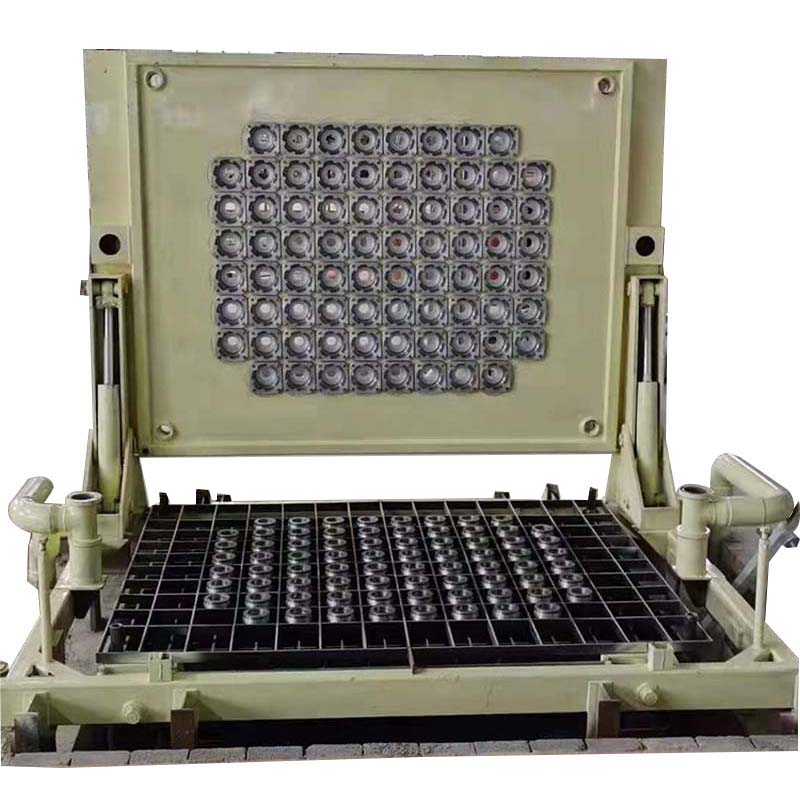

Hydraulic rooj yog ua los ntawm hydraulic zog pob, tank, tig rooj, yeeb nkab thiab li qub thiab lwm yam.

Hydraulic lub rooj nruab nrog rau khib, sab sauv pwm yog ntsia rau ntawm lub rooj hydraulic, qis pwm yog ntsia lifter khib, thaum lub sij hawm casting, lifter yuav ruber kom tsawg txwv, ces mus rau qhov siab txwv kom tiav cating los ntawm steel hlua.

Qhov Chaw Keeb Kwm:Guangdong, Suav teb

Qhov xwm txheej:Tshiab, Tshiab

Tshuab Hom:casting tshuab, tuag casting tshuab

Video tawm-kev tshuaj xyuas:Muab

Machinery Test Report:Muab

Hom kev lag luam:Cov khoom tshiab 2020

Warranty ntawm cov khoom tseem ceeb:1 Xyoo

Core Components:Gearbox, Tsav, Iav, Twj

Voltage:380V, 50HZ

Warranty:1 Xyoo

Ntsiab Muag Khoom:Yooj yim rau kev khiav lag luam

Qhov chaw Showroom:Tsis muaj

Siv tau Industries:Chaw tsim tshuaj paus

Qhov hnyav (KG):5000

Billet ntev:6 m ib

Txoj kab uas hla:70-406 hli

txoj kab uas hla:3-16 nti

txoj kev casting:kub sab saum toj casting, cua slipper casting, roj slipper casting

Daim ntawv thov:Kev lag luam Foundry

Kev siv:Round Bar

Hom:Kab rov tav Nruam Casiting Tshuab

Technology:Tsis Siv Neeg Pwm Kho

Casting tshuab txais qhov system casting (theem kaw-packed kub-sab saum toj), lub hom phiaj nyob rau hauv txoj cai txoj hauj lwm nrog dummy bar txiav, thiab yog dawb los ntawm silicic acid ntawv.

1. Casting ceev yog 0-250 mm / min (Stepless ceev regulating).Muaj ntau hom kev tiv thaiv kev ceev nrog 5-kw traction zog.

2. Tom qab ua tiav ntawm casting, casting rooj yuav tig mus rau 89 ° C ntawm lub phaj los ntawm ruaj khov hydraulic kis system.Automatic Billet Casting Tshuab.

3. Casting tshuab adots casting gystem (theem dlose-packed kub. top), targetis Kuv txoj cai postlon nrog dumy bar automatball thiab kuv dawb los ntawm icic acid ntawv.

4. Casing ceev s 0-250 mm/min (Stepless speed regulating}. Muaj ssorted antl-speed system wih 5-kw racton power.

5. Tom qab complrton ntawm caˢing, casting rooj yuav tig mus rau 89 * C n lub phaj los ntawm ruaj khov hydroulice tra nmisson system.

| Moded Nio. | Blet Size Da.x qhov siab (mm) | Blet qty (pcs) | Lub zog (hli) | Qhov hnyav ib zaug (k) | Lub kaum ntse ntse (") | Lx W (mm) |

| ALM-ZB 3.5" | 90 * 6000 hli | 54 | B | 5562 ib | 0-89 ib | 1900 * 1900 hli |

| ALMZB 5" | 0127 * 5000 | 32 | B | 5859 ua | 0-89 ib | 1800 * 1800 hli |

| AM-Z86" | 01 52 * 6000 | 20 |

| ib 5876 | 0-89 ib | 1600 * 1600 hli |

| AM-287 " | 178 * 6000 hli | 16 |

| ib 6446 | 0-89 ib | 1600 * 1600 hli |

| M-288 | 9203 * 6000 hli | 12 | B | ib 6288 | 0-89 ib | 1600 * 1600 hli |

| ALM-209 " | 9230 * 6000 hli | 8 | B | 5382 ib | 0-89 ib | 1600 * 1600 hli |

| M-2B 3.5" | 090 * 6000 hli | 100 | 11 | 10300 Nws | 0-89 ib | 2400 * 2400 hli |

| AUM-2B5" | 127 * 6000 hli | 60 | 11 | ib 10987 | 0-89 ib | 2300 * 2300 hli |

| ALMZB 5.5" | 0140 * 6000 hli | 42 | 11 | ib 10468 | 0-89 ib | 2000 * 2000 hli |

| ALM-ZB 6" | 152 * 6000 hli | 36 | 11 | ib 10577 | 0-9 | 2000 * 2000 hli |

| AM-2B7* | 178 * 6000 hli | 26 | 11 | 10476 ib | 0-89 ib | 2100 * 2100 hli |

| ALM-ZB8"; | 203 * 6000 hli | 20 | 11 | 10481 ib | 0-89 ib | 1800 * 1800 hli |

| AM-ZB9* | 230 * 6000 hli | 16 | 11 | ib 10764 | 0 ib 9 | 1800 * 1800 hli |

Remarka Technical parameters saum toj no tsuas yog rau koj siv.Finallzed detallis yog nyob rau hauv daim ntawv cog lus kawg.

1) Tib-theem kub-sab saum toj casting phaj siv cov khoom sib koom ua ke thiab faib phaj los txuas ntau cov pwm kub saum toj kawg nkaus, kom cov hlau ua kua theem hauv txhua pwm hauv tag nrho cov txheej txheem casting yog nyob rau tib theem.Nyob rau hauv tag nrho cov txheej txheem ntawm casting discs nyob rau tib theem, cov dej txhuas ntws ntws los ntawm cov yeeb yaj kiab aluminium oxide yav dhau los, uas tiv thaiv cov pa phem thib ob thiab oxidative hlawv ntawm cov hlau.

2) Nyob rau tib lub sijhawm, txhawm rau ua kom siv tag nrho cov dav hlau kab rov tav, pwm tuaj yeem tsim los ua cov pwm luv luv kom paub ntau tus pas nrig.

3) Vim tias qhov loj ntawm aluminium molten thiab tsawg cua sov dissipation nyob rau hauv txoj kev, lub casting kub yuav txo tau, thiaj li hais tias lub crystal subcooling degree yog loj, tus spontaneous nucleation tus nqi yog siab, thiab cov nplej yog refined.Ntxiv nrog rau cov yam ntxwv ntawm cov pwm luv luv, cov molten aluminium yog qhov ua tau zoo crystallization qhov siab hauv pwm yog luv dua li ntawm qhov zoo tib yam kub-sab saum toj casting, qhov tob ntawm cov kua kab noj hniav yog ntiav, cov txheej txheem ntawm cov cam khwb cia yog thinner. , cov nplej muaj ntau yam sib xws, thiab cov tsos yog smoother.

4) Cov khoom siv tau sib sau ua ke tag nrho, uas yog, lub platform casting thiab dummy puag yog positioned thiab ua ke nrog ib leeg ua ntej, thiab tom qab ntawd ntsia rau ntawm lub chassis ntawm lub tshuab casting thiab tilting mechanism, thiab siv ua ke nrog cov hlau hlua los yog hydraulic qhia kem nqa.

2. Cov khoom zoo

1) Trapezoidal tsim yog saws rau qhov ntws qhib ntawm sab sauv pwm shunt phaj, uas tuaj yeem txo qhov tshwm sim ntawm hanging aluminium thaum lub sij hawm liquidation txheej txheem, yog li ua rau kev pab cuam lub neej ntawm shunt phaj.

2) Sab saum toj tuag phaj txais kev tsim qauv ntawm cov raj coj thiab lub phaj adapter kom tsis txhob muaj qhov tshwm sim ntawm aluminizing thiab kos rau ntawm qhov chaw ntawm txhuas pas nrig, thiab tib lub sijhawm, nws tuaj yeem txo tus nqi ntawm cov khoom hnav.

3) Cov dej hauv cov dej txias txias tau txais yuav, kev txuag hluav taws xob ntawm lub phaj diverter thiab lub ntsiab zawj yog qhov zoo, qhov hloov pauv ntawm cov kua theem thaum lub sij hawm casting txheej txheem me me, thiab nws tsis yooj yim rau nqa slag thiab slag.