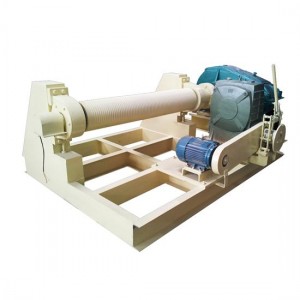

Refractory Ceramic Distributing Launder rau Aluminium billet casting

Distribution launder yog siv nyob rau hauv lub casting pwm rooj ntawm lub tshuab casting, tshwj xeeb tshaj yog haum nyob rau hauv kub-sab saum toj casting rau txhuas thiab txhuas alloy.

Distribution launder yog tsim los ntawm aluminium silicate fiber ntau thiab cov khoom siv ceramic.Nws muaj cov yam ntxwv ntawm lub zog siab;tsis kam mus rau etching kua txhuas, siv mus sij hawm ntev tsis dross, lub neej ntev, thiab zoo rwb thaiv tsev nyhuv.Nws yog qhov kev xaiv zoo tshaj plaws rau casting platform.

Distribution launder common size rau billets xws li 3", 4", 5", 6", 7", 8", 9", 10", 12", 14", 16", 18", 20", thiab kuj tuaj yeem tsim ntau qhov sib txawv raws li cov neeg siv khoom xav tau.

| Qhov ceev Kg / m3 | 135-145 : kuv |

| Flexural zog Mpa | >6 |

| SiO 2 | 60% |

| Al2O3 | 15% |

| CaO | 15% |

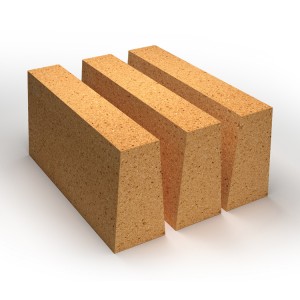

Cov yam ntxwv tseem ceeb ntawm fused silica ceramic qhov chaw yog zoo thermal rwb thaiv tsev kev ua tau zoo, kub tsis kam, tsis-stick aluminium, siab zog, tsis muaj delamination, thiab ntev kev pab cuam lub neej.Material Performance Parameters:

Kev siv lub sijhawm ntev kub (℃): 1100

Kev faib tawm qhov kub thiab txias (℃): 1650

Thermal conductivity (W / mk): <1

Qhov ceev (kg / m3): 1830

Kev tiv thaiv tawg (kg / m2): Tshuaj muaj pes tsawg leeg [SiO2]: ≥99.5

Thermal expansion coefficient (x10-6): Lub neej: 200 casting lub sij hawm los yog ntau tshaj los yog ntau tshaj 1 xyoo

1. High geometric processing raug, yooj yim rau nruab.

2. Lub zog muaj zog, lub neej ua haujlwm ntev, tus nqi tu qis.

3. Cov khoom siv tsis zoo thiab cov thermal rwb thaiv tsev zoo.

4. Non-stick aluminium, tsis muaj kuab paug rau txhuas yaj.

5. Scour kuj, corrosion kuj ntawm aluminium kua Daim ntawv thov Nws yog siv rau txhuas billet casting rooj, lub molten txhuas yog poured rau hauv pwm crystallizer los ntawm Distribution launder thaum lub sij hawm casting.Nws tuaj yeem ua tau raws li cov kev cai ntawm precision casting ntawm aluminium alloy.

Txhua qhov loj tuaj yeem raug kho, muab cov duab kos lossis cov qauv ua ntej kev yuav khoom.